-

Table of Contents

- 950 MW DEWA CSP Project Honored with SolarPACES 2024 Technology Innovation Award

- Overview of the Mohammed bin Rashid Al Maktoum Solar Park

- Background and Vision

- Phase IV: A Technological Milestone

- SolarPACES 2024 Technology Innovation Award

- About SolarPACES

- Criteria and Significance

- Technological Innovations in the DEWA CSP Project

- Hybrid CSP-PV Integration

- Advanced Thermal Energy Storage

- Record-Breaking Tower Height

- Cost Efficiency and Competitive Pricing

- International Collaboration and Project Execution

- Global Consortium

- Local Economic Impact

- Case Studies and Global Relevance

- Comparative Case: Noor Ouarzazate Solar Complex, Morocco

- Replicability in Other Regions

- Environmental and Strategic Benefits

- Carbon Emissions Reduction

950 MW DEWA CSP Project Honored with SolarPACES 2024 Technology Innovation Award

In a landmark recognition of technological excellence and sustainable innovation, the 950 MW Phase IV Concentrated Solar Power (CSP) and Photovoltaic (PV) hybrid project at the Mohammed bin Rashid Al Maktoum Solar Park in Dubai has been awarded the prestigious SolarPACES 2024 Technology Innovation Award. The award was presented to Hamid Al Kindi, Sustainable Energy Manager at the Dubai Electricity and Water Authority (DEWA), by SolarPACES Chair Gilles Flamant during the closing ceremony of the SolarPACES 2024 Conference.

This accolade underscores the project’s groundbreaking contributions to the global renewable energy landscape, particularly in the field of CSP technology. The DEWA project not only sets new benchmarks in terms of scale and efficiency but also exemplifies international collaboration and the strategic integration of multiple solar technologies.

Overview of the Mohammed bin Rashid Al Maktoum Solar Park

Background and Vision

Launched in 2012, the Mohammed bin Rashid Al Maktoum Solar Park is the largest single-site solar park in the world based on the Independent Power Producer (IPP) model. Located in the desert south of Dubai, the park is a cornerstone of the Dubai Clean Energy Strategy 2050, which aims to produce 75% of Dubai’s energy from clean sources by 2050.

The solar park is being developed in multiple phases, with a planned total capacity of 5,000 MW by 2030. The 950 MW Phase IV project, which combines CSP and PV technologies, is a critical component of this vision and represents a significant leap forward in solar energy deployment.

Phase IV: A Technological Milestone

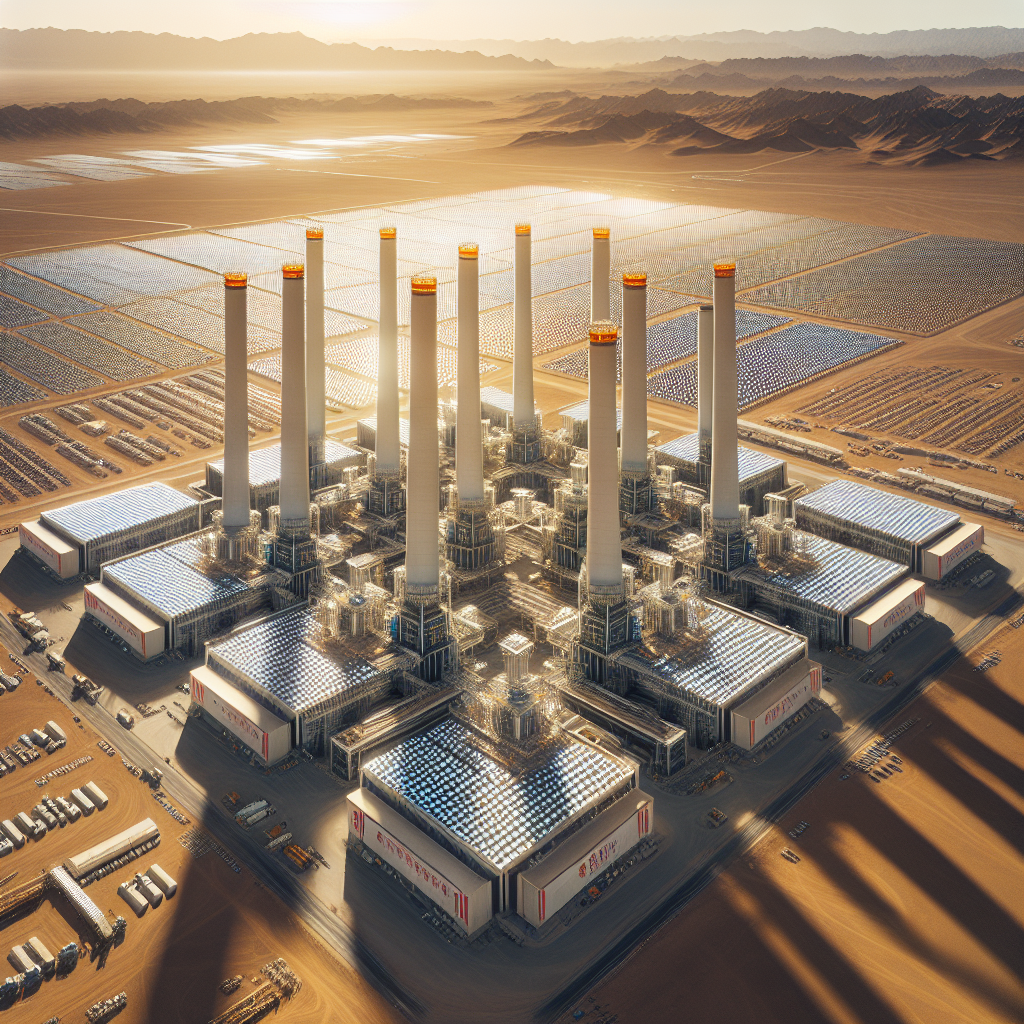

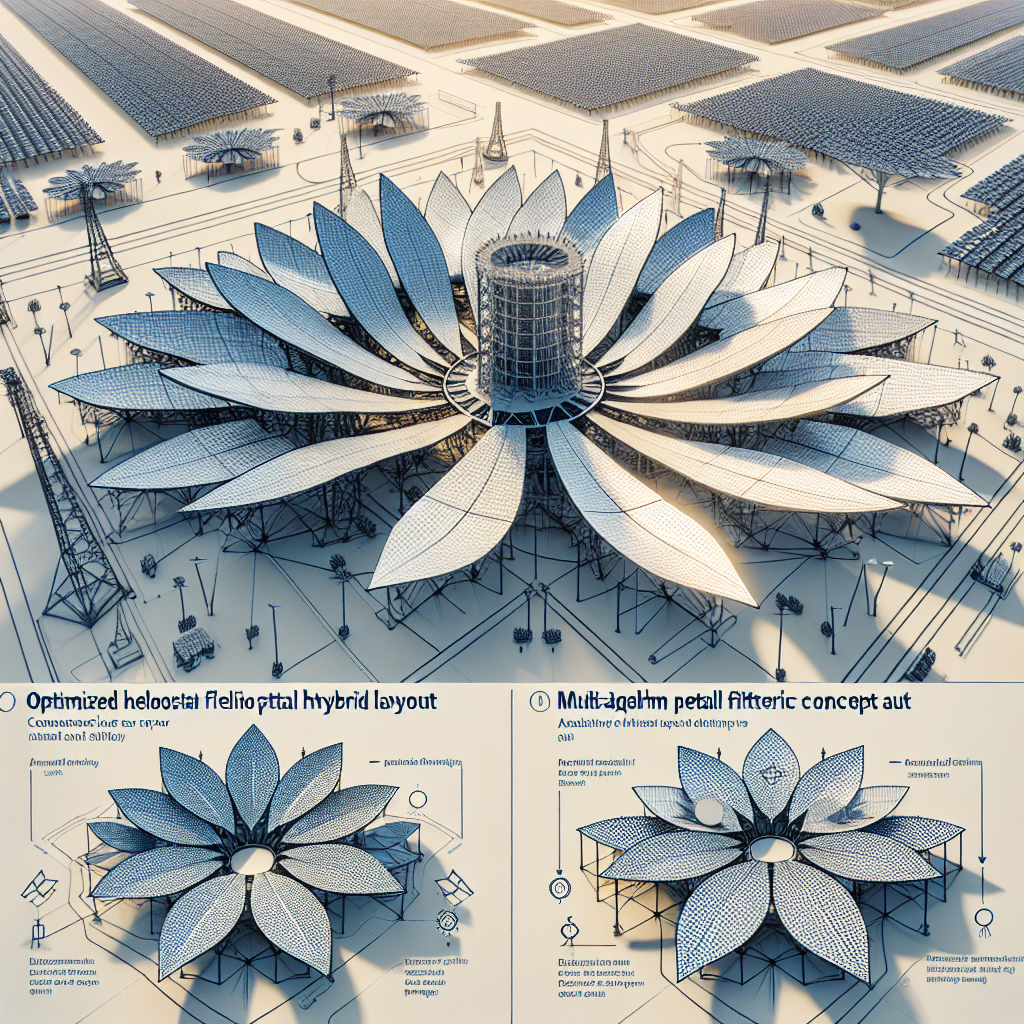

Phase IV of the solar park is the world’s largest single-site CSP project. It includes:

- 600 MW from a parabolic trough CSP system

- 100 MW from a central tower CSP system

- 250 MW from photovoltaic solar panels

This hybrid configuration allows for continuous power generation, even after sunset, thanks to advanced thermal energy storage systems. The project is being developed by Noor Energy 1, a consortium led by DEWA, ACWA Power (Saudi Arabia), and China’s Silk Road Fund.

SolarPACES 2024 Technology Innovation Award

About SolarPACES

SolarPACES (Solar Power and Chemical Energy Systems) is an international cooperative network affiliated with the International Energy Agency (IEA). It focuses on the development and deployment of CSP and solar thermal technologies. The annual SolarPACES Technology Innovation Award recognizes outstanding technological advancements that contribute to the commercialization and performance of CSP systems.

Criteria and Significance

The award is given based on several criteria, including:

- Innovation in design and engineering

- Scalability and commercial viability

- Environmental and economic impact

- Contribution to the advancement of CSP technology

Receiving this award places the DEWA Phase IV project among the most influential renewable energy initiatives globally, highlighting its role in shaping the future of sustainable power generation.

Technological Innovations in the DEWA CSP Project

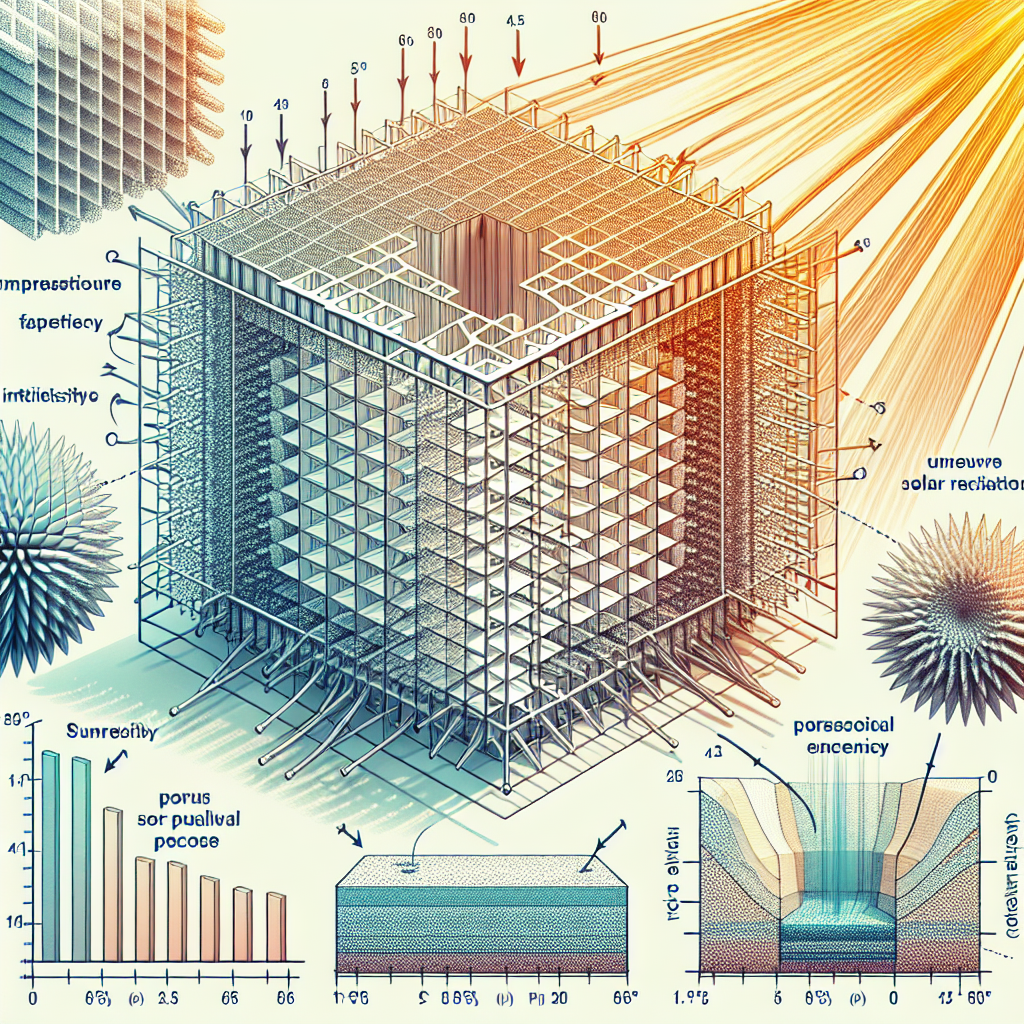

Hybrid CSP-PV Integration

One of the most innovative aspects of the DEWA project is its hybrid configuration, which combines CSP and PV technologies. This integration allows for:

- Maximized energy yield throughout the day

- Reduced intermittency and enhanced grid stability

- Optimized land use and infrastructure sharing

By leveraging the strengths of both technologies, the project ensures a more reliable and efficient energy supply.

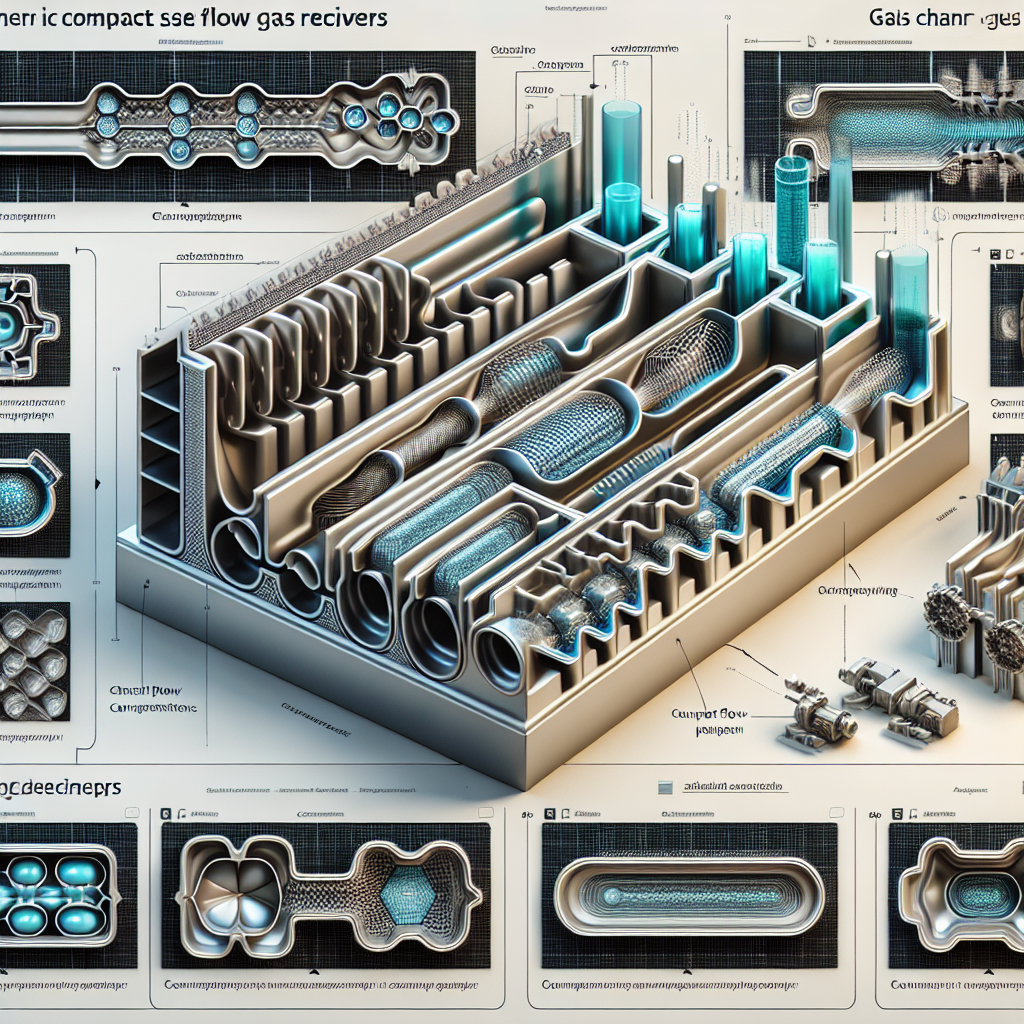

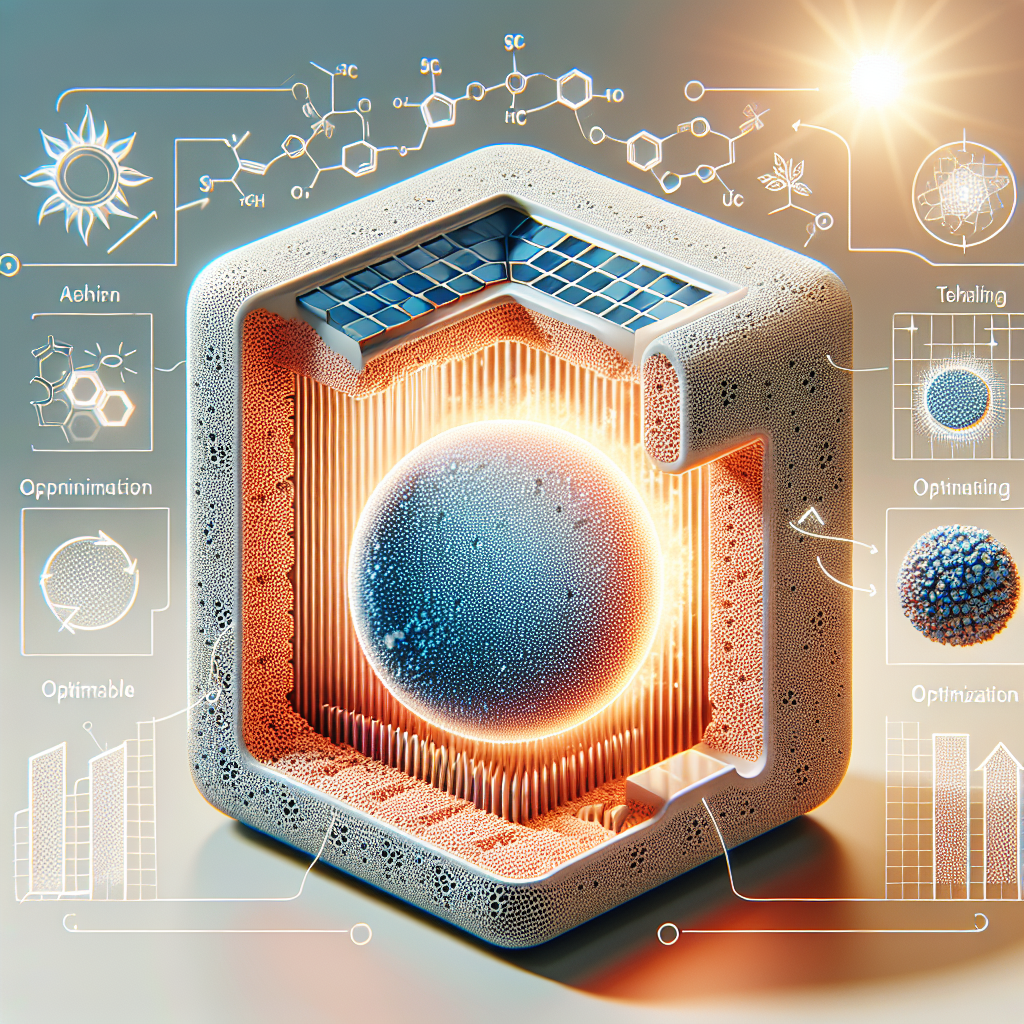

Advanced Thermal Energy Storage

The CSP components of the project are equipped with molten salt thermal energy storage systems, enabling up to 15 hours of electricity generation without sunlight. This capability is crucial for meeting peak demand periods and reducing reliance on fossil fuel-based backup systems.

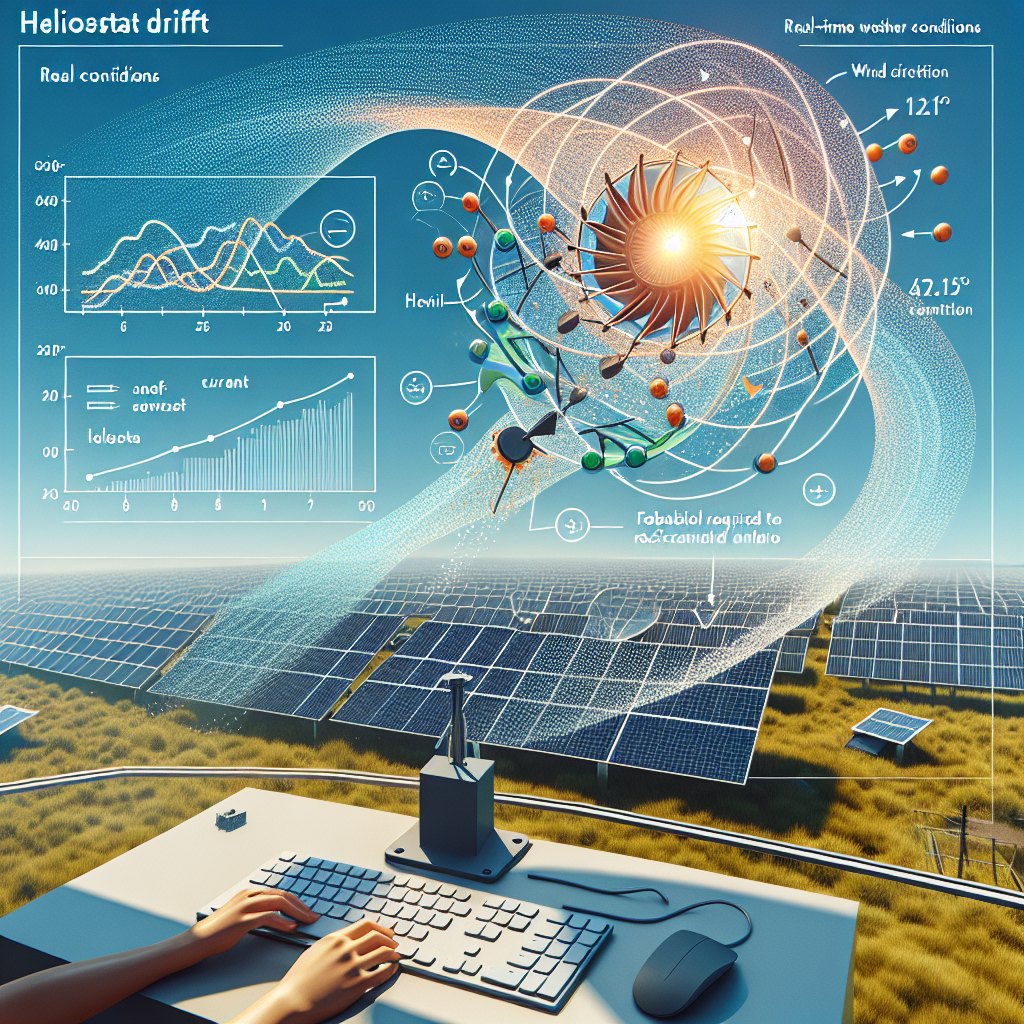

Record-Breaking Tower Height

The central tower CSP system features a solar tower that stands at 262.44 meters, making it the tallest solar tower in the world. This height allows for a larger receiver area and improved thermal efficiency, setting new standards in tower-based CSP design.

Cost Efficiency and Competitive Pricing

The project achieved a record-low Levelized Cost of Electricity (LCOE) for CSP at 7.3 US cents per kilowatt-hour. This milestone demonstrates the economic viability of large-scale CSP projects and paves the way for broader adoption in sun-rich regions.

International Collaboration and Project Execution

Global Consortium

The success of the DEWA Phase IV project is a testament to international cooperation. The consortium includes:

- DEWA – Project owner and utility provider

- ACWA Power – Lead developer and operator

- Shanghai Electric – EPC contractor and technology provider

- Silk Road Fund – Financial partner

This diverse partnership brought together expertise from the Middle East, Asia, and Europe, ensuring the highest standards in engineering, financing, and project management.

Local Economic Impact

The project has generated significant employment opportunities and contributed to the development of local supply chains. It also serves as a training ground for Emirati engineers and technicians, fostering a new generation of renewable energy professionals.

Case Studies and Global Relevance

Comparative Case: Noor Ouarzazate Solar Complex, Morocco

Before the DEWA project, Morocco’s Noor Ouarzazate complex was the largest CSP installation globally. While both projects share similarities in scale and technology, the DEWA project surpasses Noor in terms of hybrid integration and storage capacity, offering valuable insights for future CSP developments.

Replicability in Other Regions

The success of the DEWA project provides a replicable model for other sun-rich countries seeking to diversify their energy mix. Key takeaways include:

- The importance of hybrid systems for grid reliability

- The role of public-private partnerships in financing

- The need for supportive regulatory frameworks

Environmental and Strategic Benefits

Carbon Emissions Reduction

Once fully operational, the DEWA Phase IV project is expected to reduce carbon emissions by over 1.6 million tons annually. This contributes