-

Table of Contents

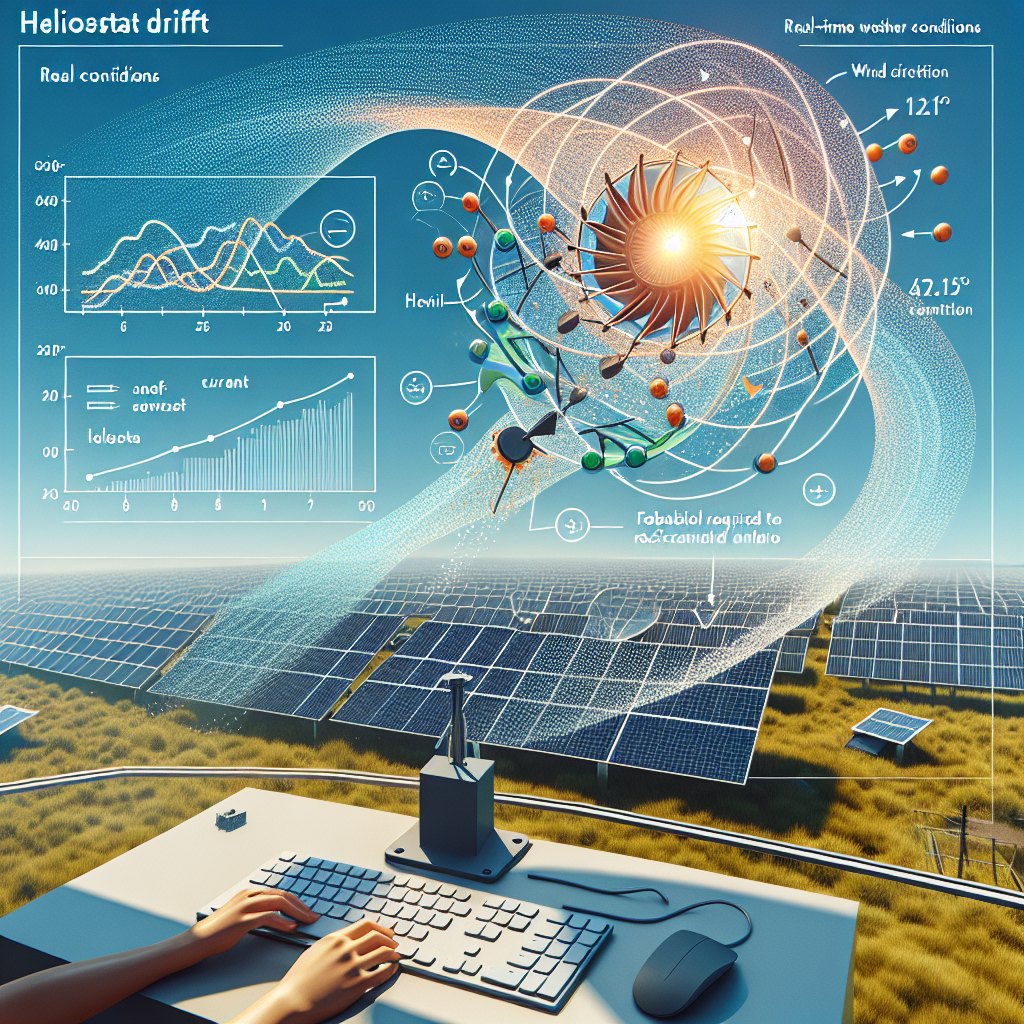

- Heliostat Drift Prediction Model for Enhanced Position Control in Solar Energy Fields

- Understanding Central Tower Solar Power Systems

- Overview of Central Tower Technology

- Importance of Heliostat Accuracy

- The Challenge of Heliostat Drift

- Causes of Drift

- Impact on System Performance

- Heliostat Drift Prediction Model (HDPM): A Game-Changer

- Concept and Development

- Key Features of HDPM

- Case Study: Implementation at a Commercial Solar Tower Plant

- Background

- Methodology

- Results

- Historical Context and Technological Evolution

- Early Heliostat Systems

- Advancements in Control Systems

- Integration with 3rd Generation CSP Technologies

- Objectives of 3rd Generation CSP

- Role of HDPM in Achieving These Goals

- Future Prospects and Research Directions

- Scalability and Global Deployment

Heliostat Drift Prediction Model for Enhanced Position Control in Solar Energy Fields

As the global demand for clean and renewable energy sources continues to rise, Concentrating Solar Power (CSP) technologies have emerged as a promising solution. Among these, Central Tower systems stand out due to their high efficiency and scalability. A critical component of these systems is the heliostat field—an array of mirrors that track the sun and reflect its rays onto a central receiver. However, maintaining the precise alignment of these heliostats over time poses significant challenges. The development and implementation of a Heliostat Drift Prediction Model (HDPM) offers a transformative approach to improving heliostat position control, thereby enhancing the overall performance and efficiency of solar energy fields.

Understanding Central Tower Solar Power Systems

Overview of Central Tower Technology

Central Tower systems, also known as solar power towers, utilize a field of heliostats to concentrate sunlight onto a central receiver mounted on a tower. The concentrated solar energy heats a working fluid, typically molten salt, which is then used to generate steam and drive a turbine for electricity production. This configuration allows for high operating temperatures and thermal storage capabilities, making it one of the most efficient CSP technologies.

Importance of Heliostat Accuracy

The efficiency of a Central Tower system is heavily dependent on the accuracy of heliostat tracking. Even minor deviations in mirror alignment can lead to significant energy losses. Over time, mechanical wear, environmental factors, and calibration errors can cause heliostats to drift from their optimal positions. This phenomenon, known as heliostat drift, necessitates frequent recalibration and maintenance, increasing operational costs and reducing system reliability.

The Challenge of Heliostat Drift

Causes of Drift

Heliostat drift can be attributed to several factors:

- Mechanical Degradation: Wear and tear on actuators and support structures can lead to misalignment.

- Thermal Expansion: Temperature fluctuations cause structural components to expand and contract, affecting positioning.

- Wind Loads: High winds can physically displace heliostats, especially in large fields.

- Control System Errors: Inaccuracies in software algorithms or sensor data can result in incorrect positioning.

Impact on System Performance

Drift reduces the amount of solar radiation that reaches the receiver, directly impacting the thermal efficiency of the system. According to studies, even a 1° misalignment can result in a 5–10% drop in reflected energy. Over time, cumulative drift across hundreds or thousands of heliostats can lead to substantial energy losses and increased operational costs due to the need for manual recalibration.

Heliostat Drift Prediction Model (HDPM): A Game-Changer

Concept and Development

The Heliostat Drift Prediction Model is a data-driven approach designed to forecast the positional deviations of heliostats over time. Developed through extensive research and field testing, the model uses historical tracking data, environmental conditions, and mechanical parameters to predict future drift patterns. This predictive capability enables proactive maintenance and real-time correction, significantly improving the accuracy and reliability of heliostat fields.

Key Features of HDPM

- Machine Learning Algorithms: HDPM employs advanced machine learning techniques to analyze large datasets and identify drift trends.

- Real-Time Monitoring: Integration with sensor networks allows for continuous monitoring of heliostat positions.

- Predictive Maintenance: The model forecasts when and where drift is likely to occur, enabling targeted interventions.

- Adaptive Control Systems: HDPM can be integrated with heliostat control software to automatically adjust mirror positions based on predicted drift.

Case Study: Implementation at a Commercial Solar Tower Plant

Background

A leading solar energy company implemented the HDPM at a 100 MW Central Tower plant located in southern Spain. The plant comprises over 10,000 heliostats, each requiring precise alignment to ensure optimal performance.

Methodology

The HDPM was integrated with the plant’s existing control system. Historical tracking data from the past three years was used to train the model. Environmental sensors provided real-time data on temperature, wind speed, and solar irradiance. The model was then used to predict drift patterns and adjust heliostat positions accordingly.

Results

- Reduction in Drift: The average angular deviation of heliostats decreased by 65% within the first six months of implementation.

- Increased Efficiency: The plant reported a 4.8% increase in annual energy output, attributed directly to improved heliostat alignment.

- Cost Savings: Maintenance costs related to manual recalibration dropped by 30%, and the frequency of required interventions was halved.

Historical Context and Technological Evolution

Early Heliostat Systems

In the early days of CSP development during the 1980s and 1990s, heliostat systems were largely mechanical and lacked sophisticated control mechanisms. Manual calibration was the norm, and drift was a persistent issue that limited scalability and efficiency.

Advancements in Control Systems

The 2000s saw the introduction of digital control systems and GPS-based tracking, which improved accuracy but still required frequent recalibration. The integration of artificial intelligence and machine learning in the 2010s marked a turning point, enabling predictive analytics and adaptive control strategies like those used in HDPM.

Integration with 3rd Generation CSP Technologies

Objectives of 3rd Generation CSP

The third generation of CSP technologies aims to achieve higher efficiency, lower costs, and improved reliability. Key objectives include:

- Operating at higher temperatures (above 600°C) to improve thermodynamic efficiency.

- Utilizing advanced materials and heat transfer fluids.

- Incorporating smart control systems for autonomous operation.

Role of HDPM in Achieving These Goals

The HDPM aligns perfectly with these objectives by enhancing the precision and reliability of heliostat fields. Its predictive capabilities reduce the need for manual intervention, support autonomous operation, and ensure that more solar energy is effectively captured and converted into electricity.

Future Prospects and Research Directions

Scalability and Global Deployment

As CSP projects expand globally, particularly in sun-rich regions like the Middle East, North