-

Table of Contents

- Enhanced Thermal Efficiency in Solar Receiver Ducts Using Louver-Punched V-Type Winglets: A Numerical and Experimental Analysis

- Background and Importance of Solar Receiver Ducts

- Role in Solar Thermal Power Plants

- Challenges in Heat Transfer

- Innovative Approach: Louver-Punched V-Type Winglets (LPVWs)

- Design and Functionality

- Advantages of LPVWs

- Methodology: Numerical and Experimental Analysis

- Computational Fluid Dynamics (CFD) Simulation

- Experimental Setup

- Key Findings and Results

- Thermal Performance Enhancement

- Pressure Drop and Friction Factor

- Optimal Configuration

- Historical Context and Related Research

- Evolution of Heat Transfer Enhancement Techniques

- Comparison with Previous Studies

- Case Study: Application in a CSP Plant

- Scenario Description

- Performance Metrics

- Environmental and Economic Impact

- Future Prospects and Recommendations

- Scalability and Integration

- Material and Manufacturing Considerations

- Hybrid Enhancement Techniques

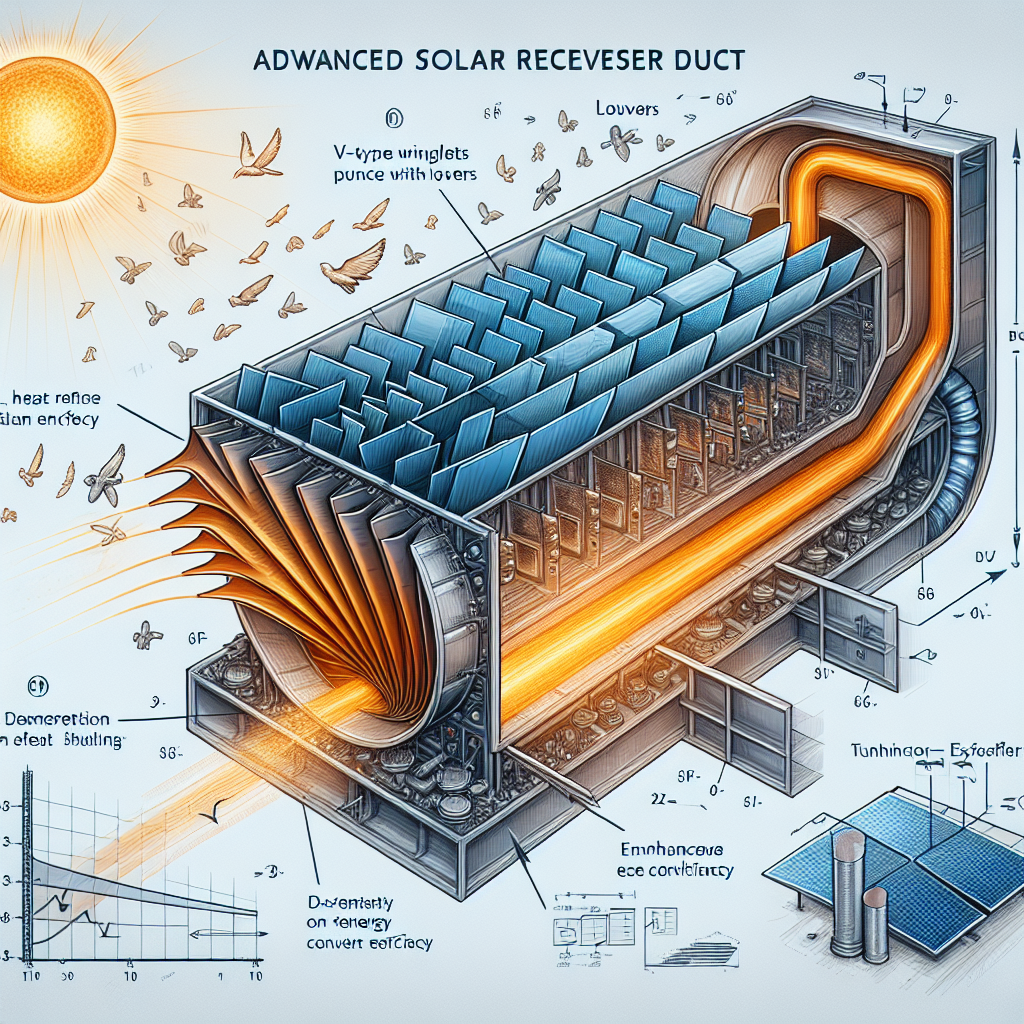

Enhanced Thermal Efficiency in Solar Receiver Ducts Using Louver-Punched V-Type Winglets: A Numerical and Experimental Analysis

As the global demand for renewable energy continues to rise, solar thermal power systems have emerged as a promising solution for sustainable electricity generation. Among the various components of a solar thermal power plant, the solar receiver duct plays a critical role in converting solar radiation into thermal energy. Improving the thermal performance of these ducts is essential for increasing the overall efficiency of solar thermal systems. A recent study titled “Enhanced Thermal Performance in Solar Receiver Duct with Louver-Punched V-Type Winglets: Numerical and Experimental Study”, published in Results in Engineering, explores a novel approach to enhancing heat transfer in solar receiver ducts using louver-punched V-type winglets (LPVWs).

Background and Importance of Solar Receiver Ducts

Role in Solar Thermal Power Plants

Solar receiver ducts are integral to Concentrated Solar Power (CSP) systems, particularly in central receiver and linear Fresnel systems. These ducts house the absorber plate, which captures and transfers solar energy to a working fluid. The efficiency of this heat transfer process directly impacts the overall performance of the power plant.

Challenges in Heat Transfer

One of the primary challenges in solar receiver ducts is the limited rate of convective heat transfer due to laminar or weakly turbulent flow conditions. Traditional methods to enhance heat transfer, such as increasing the surface area or using extended surfaces (fins), often result in increased pressure drop and energy consumption for fluid pumping.

Innovative Approach: Louver-Punched V-Type Winglets (LPVWs)

Design and Functionality

The study introduces LPVWs as a passive heat transfer enhancement technique. These winglets are V-shaped structures punched with louvers and attached to the absorber plate inside the duct. The V-type configuration promotes flow separation and reattachment, while the louvers induce secondary swirling flows, enhancing turbulence and mixing near the wall surface.

Advantages of LPVWs

- Increased turbulence intensity near the absorber plate

- Enhanced convective heat transfer without significant pressure drop

- Simple and cost-effective fabrication

- Compatibility with existing duct designs

Methodology: Numerical and Experimental Analysis

Computational Fluid Dynamics (CFD) Simulation

The researchers employed a three-dimensional CFD model using the realizable k-ε turbulence model to simulate the flow and heat transfer characteristics within the solar receiver duct. The model accounted for the geometry of the LPVWs, thermal boundary conditions, and fluid properties. Grid independence tests and validation against experimental data ensured the reliability of the simulation results.

Experimental Setup

An experimental test rig was constructed to validate the numerical findings. The setup included a rectangular duct with a heated absorber plate, LPVWs installed at regular intervals, and instrumentation to measure temperature, pressure, and flow rate. The experiments were conducted under steady-state conditions with air as the working fluid.

Key Findings and Results

Thermal Performance Enhancement

The study reported a significant improvement in the Nusselt number (Nu), a dimensionless parameter representing convective heat transfer. Compared to a smooth duct, the LPVW-enhanced duct exhibited up to a 2.5-fold increase in Nu, indicating a substantial enhancement in heat transfer efficiency.

Pressure Drop and Friction Factor

While the introduction of LPVWs increased the friction factor due to flow obstruction, the rise was moderate and within acceptable limits. The thermal performance factor (TPF), which considers both heat transfer and pressure drop, remained above unity for all tested configurations, confirming the overall benefit of the LPVWs.

Optimal Configuration

The study identified that the best performance was achieved with a winglet angle of 45° and a louver pitch of 10 mm. This configuration provided the highest TPF, balancing heat transfer enhancement and pressure loss.

Historical Context and Related Research

Evolution of Heat Transfer Enhancement Techniques

Heat transfer augmentation has been a subject of extensive research since the mid-20th century. Early methods focused on extended surfaces and surface roughness. In recent decades, vortex generators such as delta wings and rectangular winglets have gained popularity due to their ability to enhance turbulence without excessive pressure drop.

Comparison with Previous Studies

Previous studies using plain V-type winglets or delta winglets reported Nu enhancements of 1.5 to 2 times. The introduction of louvers in the current study further increased turbulence intensity, leading to superior performance. This innovation represents a significant advancement in passive heat transfer enhancement techniques.

Case Study: Application in a CSP Plant

Scenario Description

To assess the practical implications of the LPVW design, the researchers simulated its application in a 50 MW CSP plant operating in a desert environment. The plant used air as the heat transfer fluid and operated at an inlet temperature of 300°C and a mass flow rate of 1.5 kg/s per duct.

Performance Metrics

- Baseline (Smooth Duct): Thermal efficiency of 65%

- With LPVWs: Thermal efficiency increased to 78%

- Pressure Drop Increase: 12%, manageable with existing blower capacity

- Payback Period: Less than 2 years due to increased energy output

Environmental and Economic Impact

The enhanced efficiency translated to an additional 6.5 GWh of electricity annually, reducing CO₂ emissions by approximately 4,500 tons per year. The cost of retrofitting existing ducts with LPVWs was minimal compared to the long-term energy gains.

Future Prospects and Recommendations

Scalability and Integration

The LPVW design is scalable and can be integrated into various CSP technologies, including parabolic troughs and linear Fresnel systems. Its passive nature makes it suitable for remote or off-grid installations where maintenance and energy consumption must be minimized.

Material and Manufacturing Considerations

Future research should explore the use of high-temperature alloys or ceramic composites for LPVWs to withstand extreme operating conditions. Additive manufacturing techniques could enable complex geometries and rapid prototyping.

Hybrid Enhancement Techniques

Combining LPVWs with other enhancement methods, such as nanofluids or phase change materials, could further boost thermal performance