-

Table of Contents

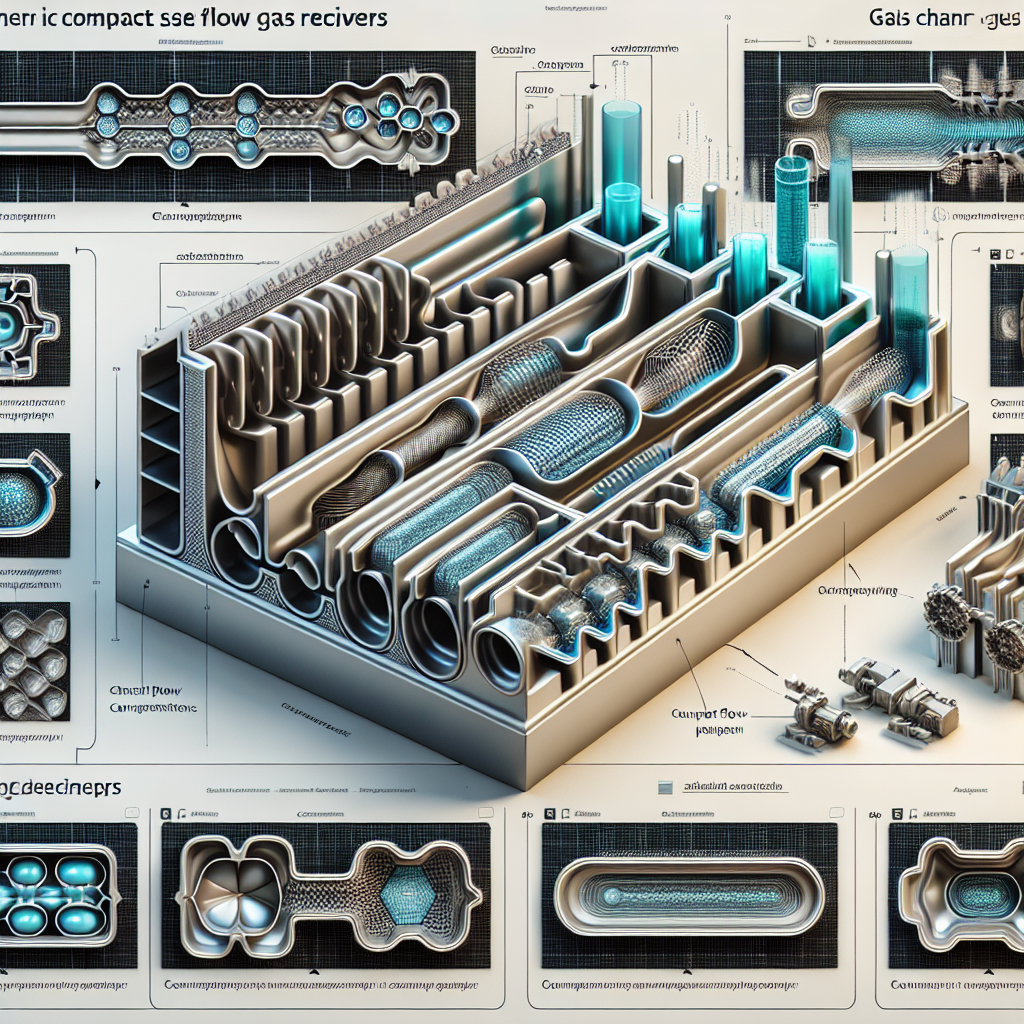

- Optimizing Channel Geometry for Compact Flow Gas Receivers in Concentrated Solar Power Systems

- The Role of Compact Flow Gas Receivers in CSP

- Why Use Gases as Working Fluids?

- Channel Geometry: A Key to Thermal Efficiency

- Heat Transfer Mechanisms in Gas Receivers

- Research Insights: Finding the Ideal Channel Geometry

- Case Study: ETH Zurich’s Experimental Receiver

- Computational Fluid Dynamics (CFD) Simulations

- Design Trade-offs and Engineering Challenges

- Material Considerations

- Historical Context and Evolution of Receiver Design

Optimizing Channel Geometry for Compact Flow Gas Receivers in Concentrated Solar Power Systems

In the realm of renewable energy, concentrated solar power (CSP) stands out for its ability to generate dispatchable electricity by storing thermal energy. A critical component of CSP systems is the solar receiver, which absorbs concentrated sunlight and transfers the heat to a working fluid. For high-temperature applications such as solar thermochemistry, where temperatures can reach up to 1400°C, the choice of working fluid and the design of the receiver become pivotal. Gaseous heat transfer media like air are gaining attention due to their abundance, non-toxicity, and thermal stability. However, gases have lower heat transfer coefficients compared to liquids, making the optimization of receiver design—particularly the internal channel geometry—essential for efficient operation.

The Role of Compact Flow Gas Receivers in CSP

Compact flow gas receivers are designed to maximize heat transfer between concentrated solar radiation and a gaseous working fluid. These receivers are typically composed of a network of channels through which the gas flows, absorbing heat from the receiver walls. The geometry of these channels significantly influences the thermal performance, pressure drop, and overall efficiency of the system.

Why Use Gases as Working Fluids?

Gases such as air, nitrogen, or carbon dioxide offer several advantages in CSP applications:

- High-temperature stability: Unlike liquids, gases do not boil or degrade at high temperatures, making them suitable for thermochemical processes.

- Environmental safety: Gases like air are non-toxic and readily available, reducing environmental and safety concerns.

- Cost-effectiveness: Gases are generally cheaper and easier to handle than specialized heat transfer fluids.

However, the low density and specific heat capacity of gases mean that they require careful engineering to achieve efficient heat transfer. This is where channel geometry becomes a critical design parameter.

Channel Geometry: A Key to Thermal Efficiency

The internal geometry of a gas receiver determines how effectively heat is transferred from the receiver walls to the gas. Several geometric parameters influence this process:

- Channel shape (circular, rectangular, triangular, etc.)

- Channel size and aspect ratio

- Surface area-to-volume ratio

- Flow path length and complexity

- Wall thickness and material conductivity

Optimizing these parameters can enhance convective heat transfer, reduce pressure losses, and improve the overall thermal efficiency of the receiver.

Heat Transfer Mechanisms in Gas Receivers

Heat transfer in compact flow gas receivers occurs primarily through convection and conduction. Radiative heat transfer from the solar flux is absorbed by the receiver walls, which then conduct the heat to the internal surfaces. The gas flowing through the channels picks up this heat via convection. Enhancing the convective heat transfer coefficient is crucial, and this can be achieved by manipulating the channel geometry to promote turbulence or increase surface area.

Research Insights: Finding the Ideal Channel Geometry

Recent research, such as that highlighted in the SolarPACES article “Finding an ideal channel geometry inside compact flow gas receivers”, has focused on identifying optimal geometries that balance heat transfer efficiency with manufacturability and pressure drop constraints.

Case Study: ETH Zurich’s Experimental Receiver

Researchers at ETH Zurich developed a compact flow gas receiver designed for high-temperature solar thermochemical applications. The receiver was tested with air as the working fluid and operated at temperatures exceeding 1000°C. The team experimented with various channel geometries, including:

- Rectangular channels with varying aspect ratios

- Hexagonal honeycomb structures

- Spiral and serpentine flow paths

The study found that hexagonal channels offered a good compromise between structural integrity and thermal performance. These geometries provided a high surface area-to-volume ratio, which enhanced convective heat transfer without causing excessive pressure drops.

Computational Fluid Dynamics (CFD) Simulations

To complement experimental work, researchers employed CFD simulations to model heat transfer and fluid flow within different channel geometries. These simulations allowed for the analysis of temperature gradients, velocity profiles, and pressure losses under various operating conditions. The results confirmed that:

- Smaller channels increase heat transfer but also raise pressure drop.

- Curved or spiral channels promote turbulence, enhancing heat transfer.

- Uniform flow distribution is critical to avoid hot spots and material degradation.

Design Trade-offs and Engineering Challenges

While optimizing channel geometry can significantly improve performance, it also introduces engineering challenges. Designers must balance several competing factors:

- Thermal Efficiency vs. Pressure Drop: Increasing surface area improves heat transfer but also increases frictional losses.

- Manufacturability: Complex geometries may be difficult or expensive to fabricate, especially at high temperatures.

- Material Constraints: High-temperature operation limits the choice of materials, which must withstand thermal stress and oxidation.

- Scalability: Designs must be scalable for commercial deployment without compromising performance.

Material Considerations

Materials used in compact flow gas receivers must endure extreme temperatures and thermal cycling. Common choices include:

- Ceramics (e.g., silicon carbide)

- High-temperature alloys (e.g., Inconel)

- Refractory metals (e.g., tungsten)

These materials must also be compatible with the working gas to prevent corrosion or chemical reactions that could degrade performance over time.

Historical Context and Evolution of Receiver Design

The concept of using gas as a heat transfer medium in solar receivers dates back to early CSP experiments in the 1970s. However, the low heat transfer efficiency of gases limited their adoption. With advances in materials science, computational modeling, and additive manufacturing, modern designs are overcoming these limitations.

Notable milestones include:

- 1980s: Development of volumetric air receivers for solar towers.

- 2000s: Introduction of ceramic honeycomb structures to improve heat transfer.

- 2010s: Integration of CFD and optimization algorithms in receiver design.

- <strong